Product Categories

- > Digital Textile Printer

-

- Fedar Sublimation Textile Printer

FEDAR FD61916E Sublimation Printer FEDAR FD1924 Sublimation Printer FEDAR FD1912S Sublimation Printer FEDAR FD61915E-A Sublimation Printer FEDAR FD5198E Sublimation Printer FEDAR FD51915E Sublimation Printer FEDAR FD53215E Sublimation Printer FEDAR FD61915E Sublimation Printer FD6198E 8 Heads Printer FD6194E 4 Heads Printer Fedar FD Series Sublimation Printer(6heads,8heads) FD5328E 3.2m Printer FD5193E 3 Heads Printer Fedar TC Series Sublimation Printer(3heads,4heads,6heads)(Stop) FD5268E 2.6m Printer FD5223E 2.2m Printer (Stop) FD1900 2 Heads Printer AL193 3 Heads Printer (Stop) TC1932 2 Heads Printer (Stop)

- Fedar Direct Textile Printer

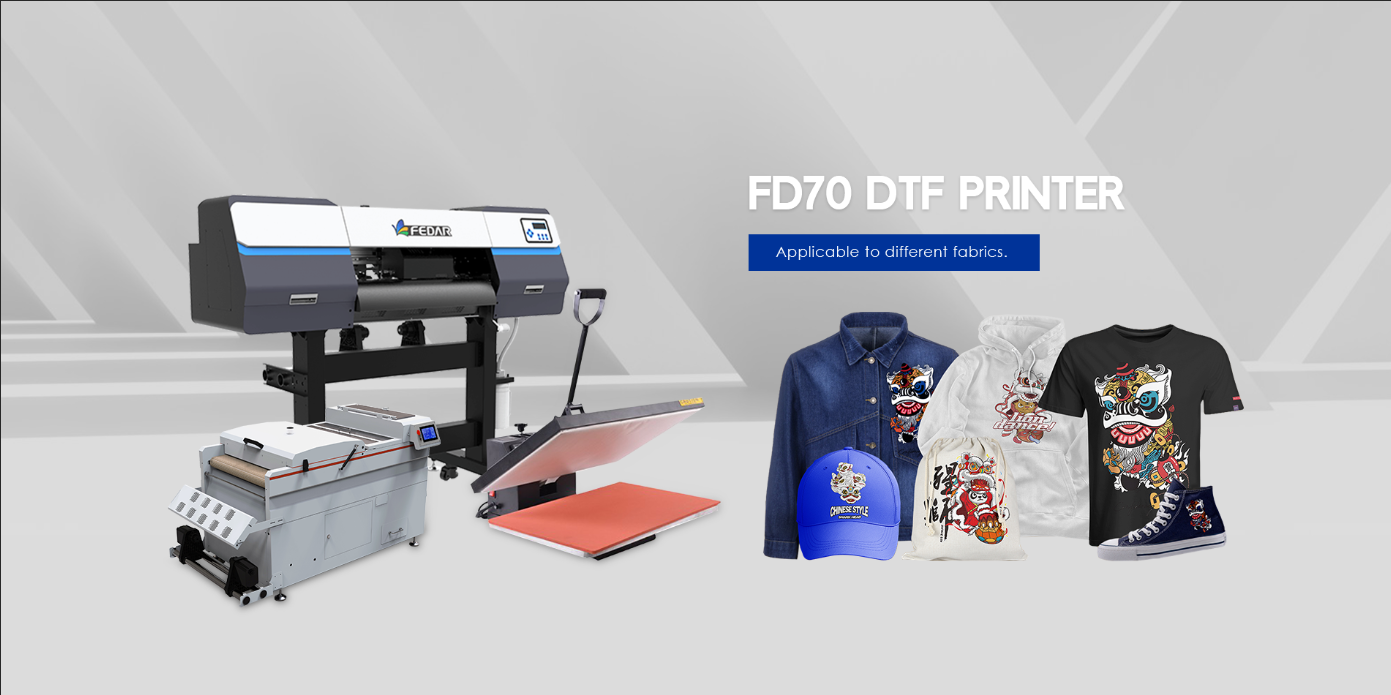

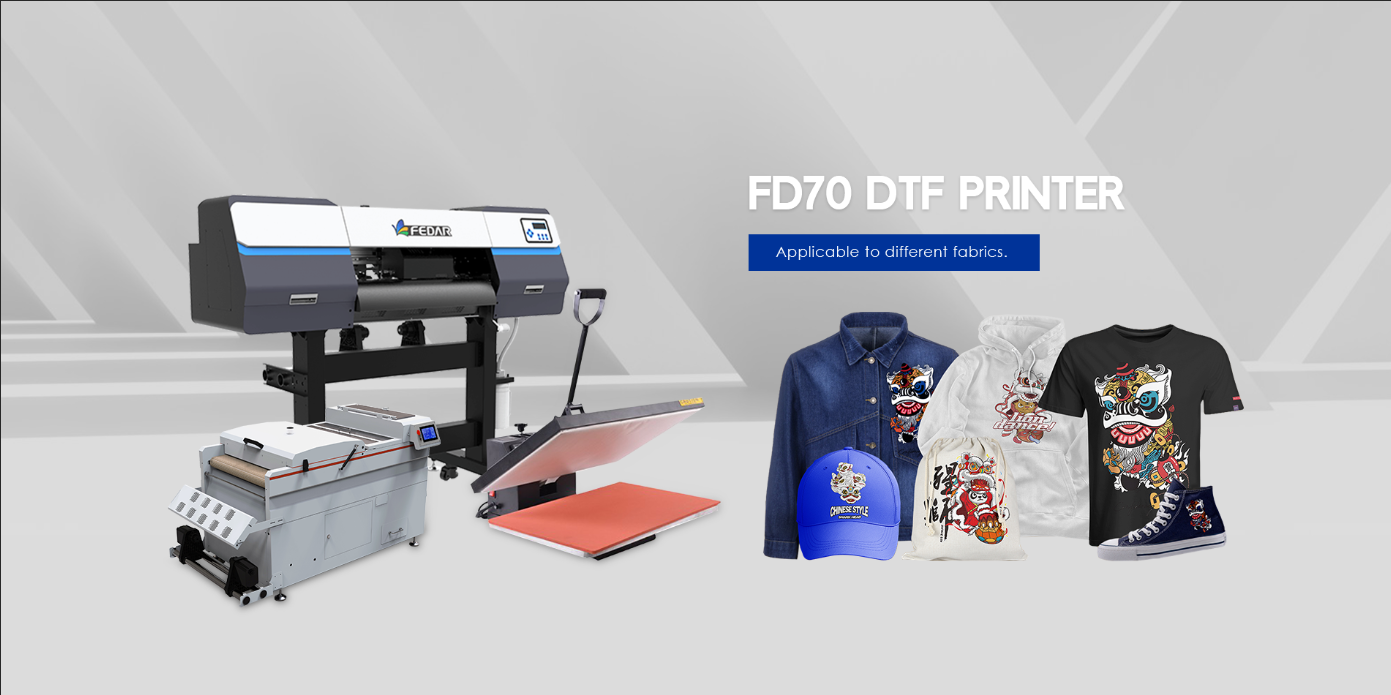

FD70-3 DTF Printer FD30 DTF Printer FD60 DTF Printer FD70-4 DTF Printer FD65-2 DTF Printer FD70-2 DTF Printer TR 4180 (Stop) FD 680 DTG (Stop) FD1828 Belt cotton printer (Stop)

- Fedar Sublimation Textile Printer

DTF Printing vs Sublimation Printing: What Are the Differences?

2023-08-03

DTF Printing:

DTF (Direct To Film) printing is a relatively new and innovative method that has gained attention in the printing industry. This technique involves transferring designs directly onto a special film using DTF ink and a high-quality DTF printer. The printed design on the film is then heat pressed onto the fabric, allowing the ink to penetrate and adhere to the fabric's fibers. This process enables vibrant and long-lasting prints on a wide range of materials, including cotton, polyester, and blends.

Advantages of DTF Printing:

1. Compatibility: DTF printing works well with various fabric types, making it versatile for different garment options.

2. Vibrant Colors: DTF printing uses high-quality, pigmented inks that result in vibrant and vivid colors on fabrics, ensuring your designs capture attention.

3. Durability: The ink used in DTF printing is known for its durability. It resists fading and cracking, even after multiple washes, ensuring your prints maintain their quality for longer periods.

4. Detailed Designs: DTF printing allows for intricate design details and gradients, making it suitable for complex patterns and artwork.

Sublimation Printing:

Sublimation printing, on the other hand, involves printing designs onto a special sublimation paper using sublimation ink by a high-quality sublimation printer. The paper is then heat pressed onto the fabric, causing the ink to convert into gas and permeate the fabric's fibers permanently. This process creates a seamless integration of the design with the fabric, resulting in vibrant and durable prints.

Advantages of Sublimation Printing:

1. Unlimited Color Options: Sublimation printing allows for an extensive color gamut, enabling you to create designs with unlimited color options. The ink is infused directly into the fabric, resulting in vivid prints.

2. Breathability: Since sublimation printing dyes the fabric rather than sitting on top of it, the prints retain the fabric's breathability, making it ideal for athletic wear and performance fabrics.

3. Fade and Crack Resistant: Sublimation prints are long-lasting and resistant to fading or cracking, even after multiple washing cycles.

4. Fast Turnaround Time: Sublimation printing offers a quick turnaround as the process is relatively fast, allowing for efficient production cycles.

Choosing the Right Method:

The choice between DTF printing and sublimation printing will ultimately depend on your specific requirements. Here are a few factors to consider:

1. Fabric Type: If you primarily work with natural fabrics like cotton, DTF printer may be a better option. However, sublimation printer is ideal for synthetic or blended fabrics like polyester.

2. Design Complexity: If your designs involve intricate details and gradients, DTF printing might be more suitable due to its ability to reproduce fine details accurately.

3. Color Variation: If your designs require a wide range of vibrant colors, sublimation printer allows for unlimited color options, giving you more creative freedom.

4. Production Volume: Consider the volume of production you require. Sublimation printing is faster, making it more suitable for large-scale production, while DTF printing may be ideal for smaller quantities.

In conclusion, both DTF printing and sublimation printing are excellent choices for fabric printing, each with its own unique advantages. Assessing your specific needs and considering factors like fabric type, design complexity, color variation, and production volume will help you make a well-informed decision. Whichever method you choose, both FEDAR DTF Printer and FEDAR Sublimation Printer offer exceptional results that will bring your designs to life on fabric.