Product Categories

- > Digital Textile Printer

-

- Sublimation Textile Printer

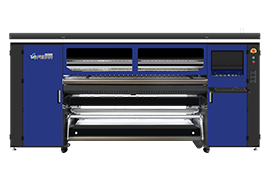

FEDAR FD1924 Sublimation Printer FEDAR FD1912S Sublimation Printer FEDAR FD61915E-A Sublimation Printer FEDAR FD5198E Sublimation Printer FEDAR FD51915E Sublimation Printer FEDAR FD53215E Sublimation Printer FEDAR FD61915E Sublimation Printer FD6198E 8 Heads Printer FD6194E 4 Heads Printer Fedar FD Series Sublimation Printer(6heads,8heads) FD5328E 3.2m Printer FD5193E 3 Heads Printer Fedar TC Series Sublimation Printer(3heads,4heads,6heads) FD5268E 2.6m Printer FD5223E 2.2m Printer FD1900 2 Heads Printer AL193 3 Heads Printer TC1932 2 Heads Printer

- Direct Textile Printer

FD70-3 DTF Printer FD30 DTF Printer FD60 DTF Printer FD70-4 DTF Printer FD65-2 DTF Printer FD70-2 DTF Printer TR 4180 FD 680 DTG FD1828 Belt cotton printer

- Sublimation Textile Printer

How to eliminate the bandings during printing?

2022-07-19

In daily print working, some bandings may be found, what’s the cause of it and how to avoid it?

1. Discontinuity of inkjet

Firstly, confirm whether the nozzle status is normal before printing. If nozzle got missing, please use the nozzle maintenance function, and then print until the nozzle status get normal..

Secondly, nozzle missing during printing. Pay attention to whether there is ink drop on the surface of the head. If yes, the damper may leak, and the damper in the channel should be replaced. If there is no extra ink on the head, it is necessary to confirm whether the ink used by the machine is the original ink, and confirm whether the ink has expired (the shelf life of unopened ink is generally about one year, and the shelf life of opened ink is generally about three months).

Note: There are many inks on the market. Original ink is suggested. The original ink has been tested by the factory for a long time, and the untested ink may have risk of clogging nozzles.

2. Step motor is not well calibrated.

It is better recalibrate the step motor and make sure the media moving is exact and ink droplet can be jetted into correct position.

3. Too much pressure from pitch roller

Too much pressure from pinch roller may result in the media out of shape during printing, the slight height difference on media will cause the bandings in the print.

4. The problem of the material itself

Firstly, the material damp or deteriorated due to long storage time. We recommend printing on material with a newer date.

Secondly, the coating on the surface of the material is not uniform. There are many specifications and models of materials on the market, but each manufacturer uses different materials and workmanship. When some brands of materials and workmanship are relatively poor, it is easy to have the print issue. Material from name brand is suggested.